Workshop:

various leather

various hardware

various types of thread

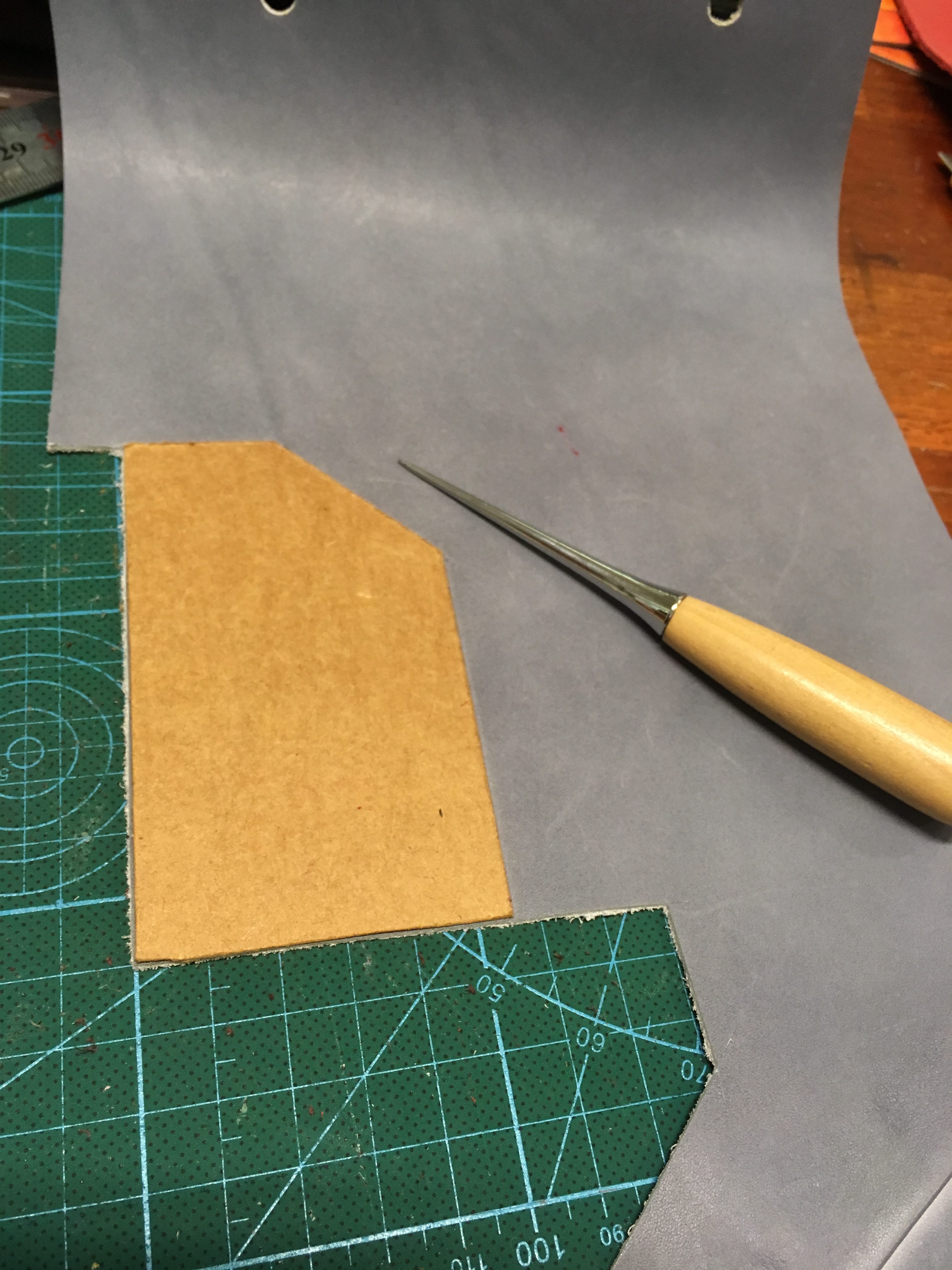

Tools:

- Ruler

- Penknife

- Cutting Mat

- Creaser

- Scratch Awl

- Hammar

- Fork

- File

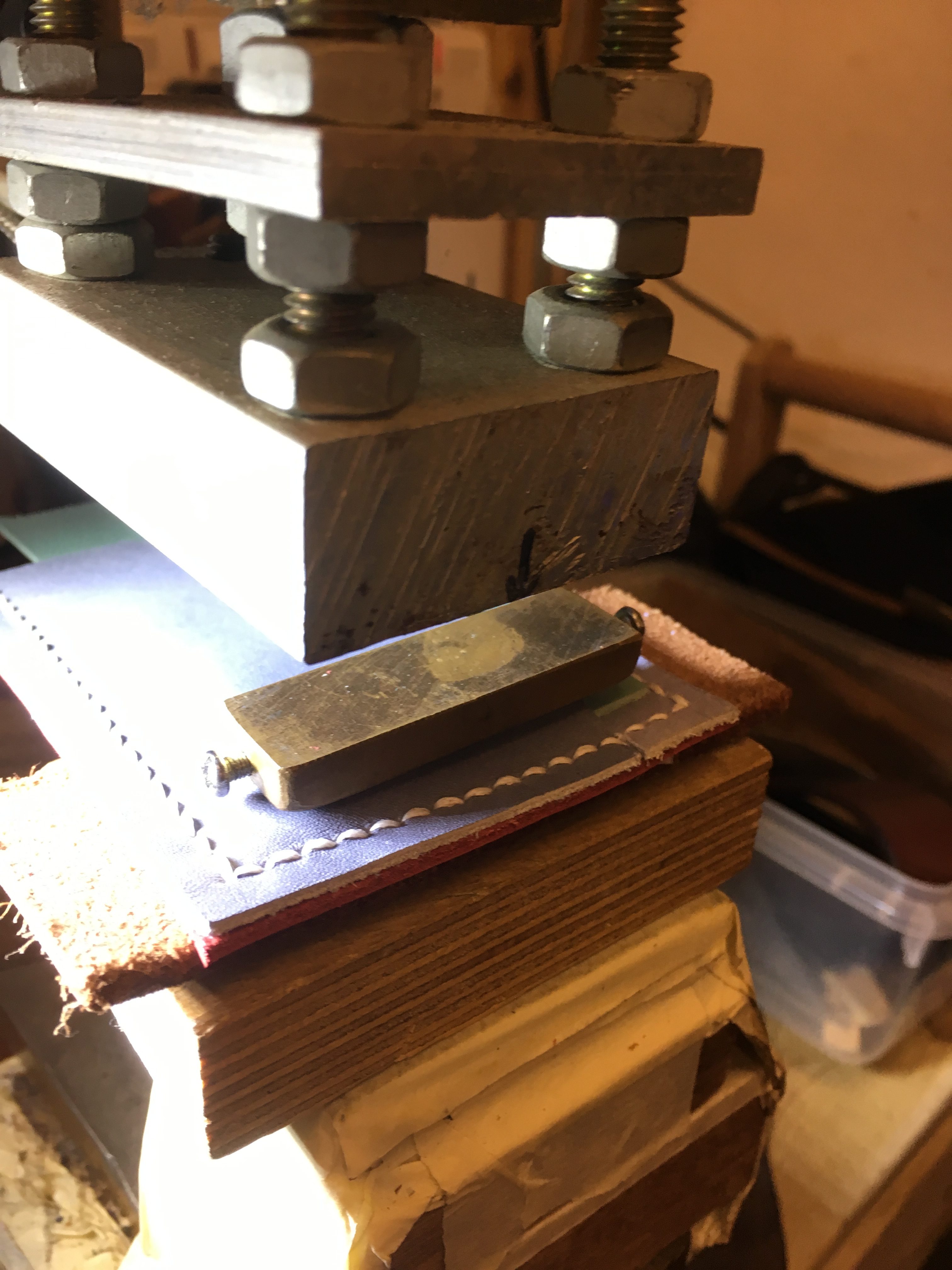

- Thick Board

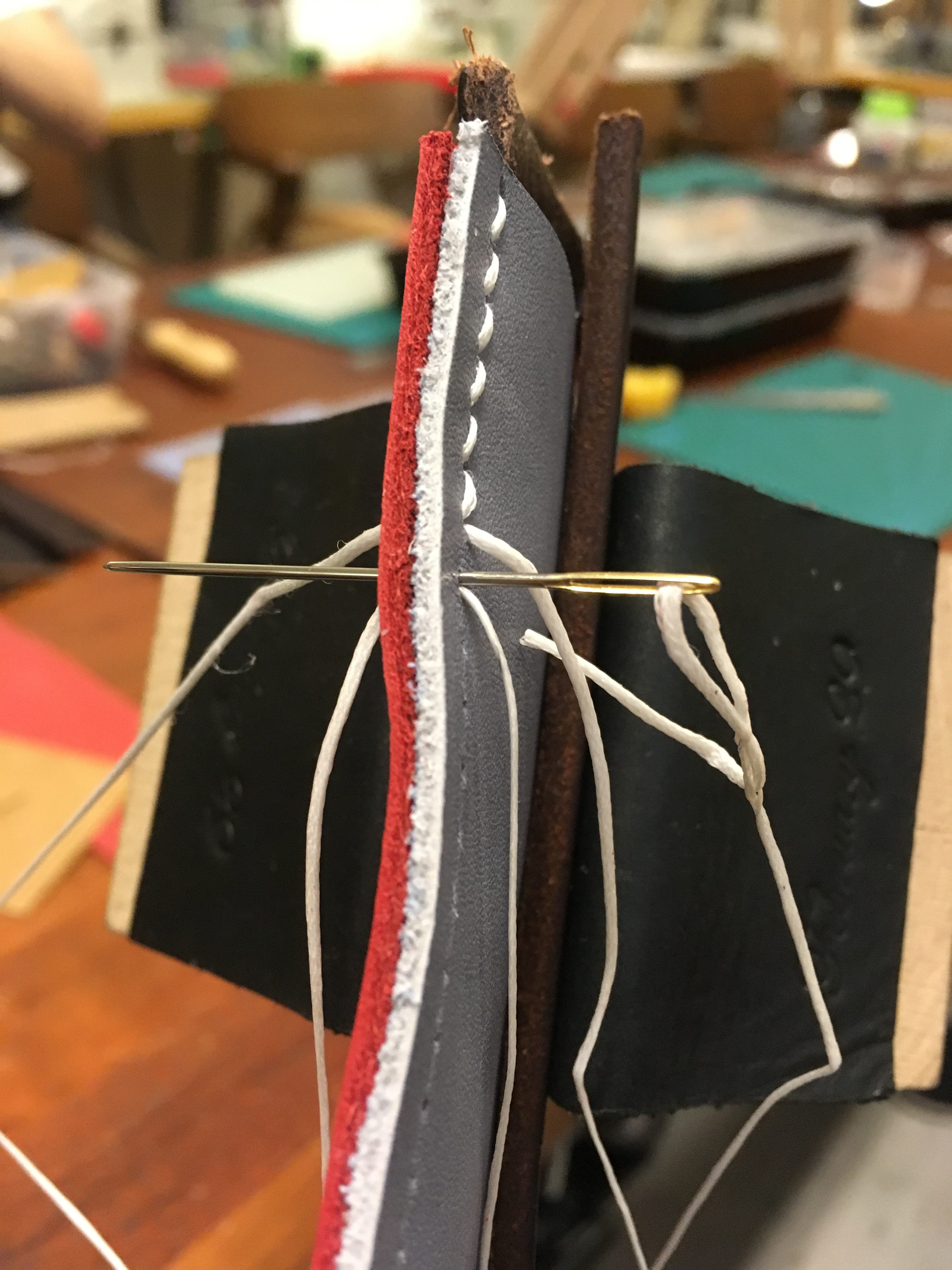

- Needle

- Thread

- Wax (not pictured)

- Clamp

- Heat Debossing Machine and letters

Process:

Step 1. Choose leather

Step 2. Use the scratch awl to lightly indent guide lines for cutting

Step 3. Cut the leather into desired shape and size

Step 4. Use the creaser to indent guide lines for sewing

Step 5. Use the fork to lightly indent where the holes are going to be

Step 6. Using the hammer and fork, punch holes into the leather

Step 7. Choose desired thread and thread it through the needle

Step 8. Clamp the leather pieces together and start sewing

Step 9. If desired, deboss letters into the final product

Pain Points:

Depending on the hardness and thickness of the leather, it can actually be quite delicate. For example, when cutting a thin piece of leather, one has to be very careful not to stretch it out.

Precision is also very important, especially when the product is meant to be sold.

Finally, lots of strength is actually needed, especially during the process of punching holes into the leather.