Process Documentation/Practice:

We paid a visit to Sticky, a business that makes custom rock candy confectionery. The candy is completely hand-made. After asking the practitioners permission to observe and partake in the process, we were able to see the entire process of making a custom order.

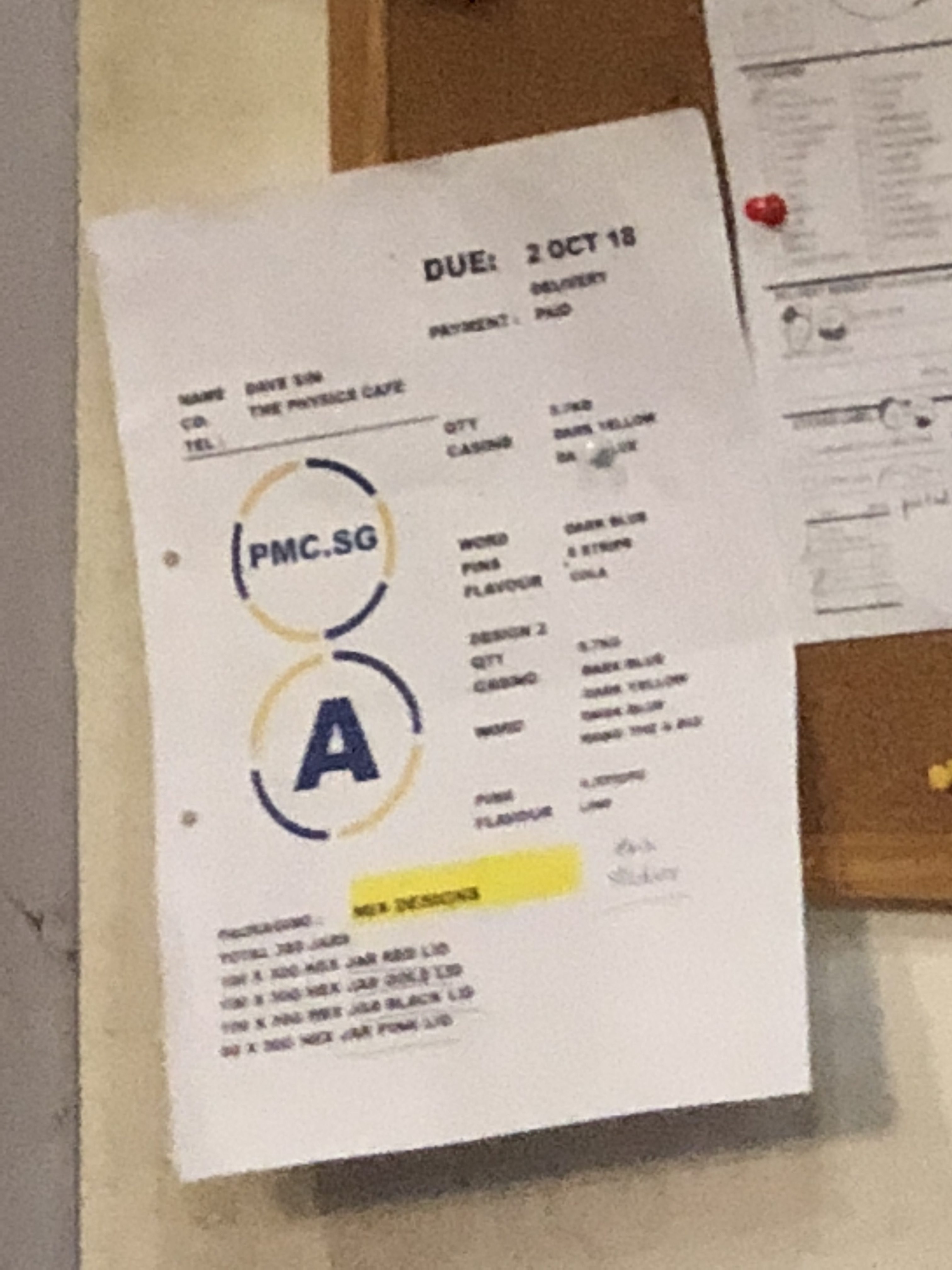

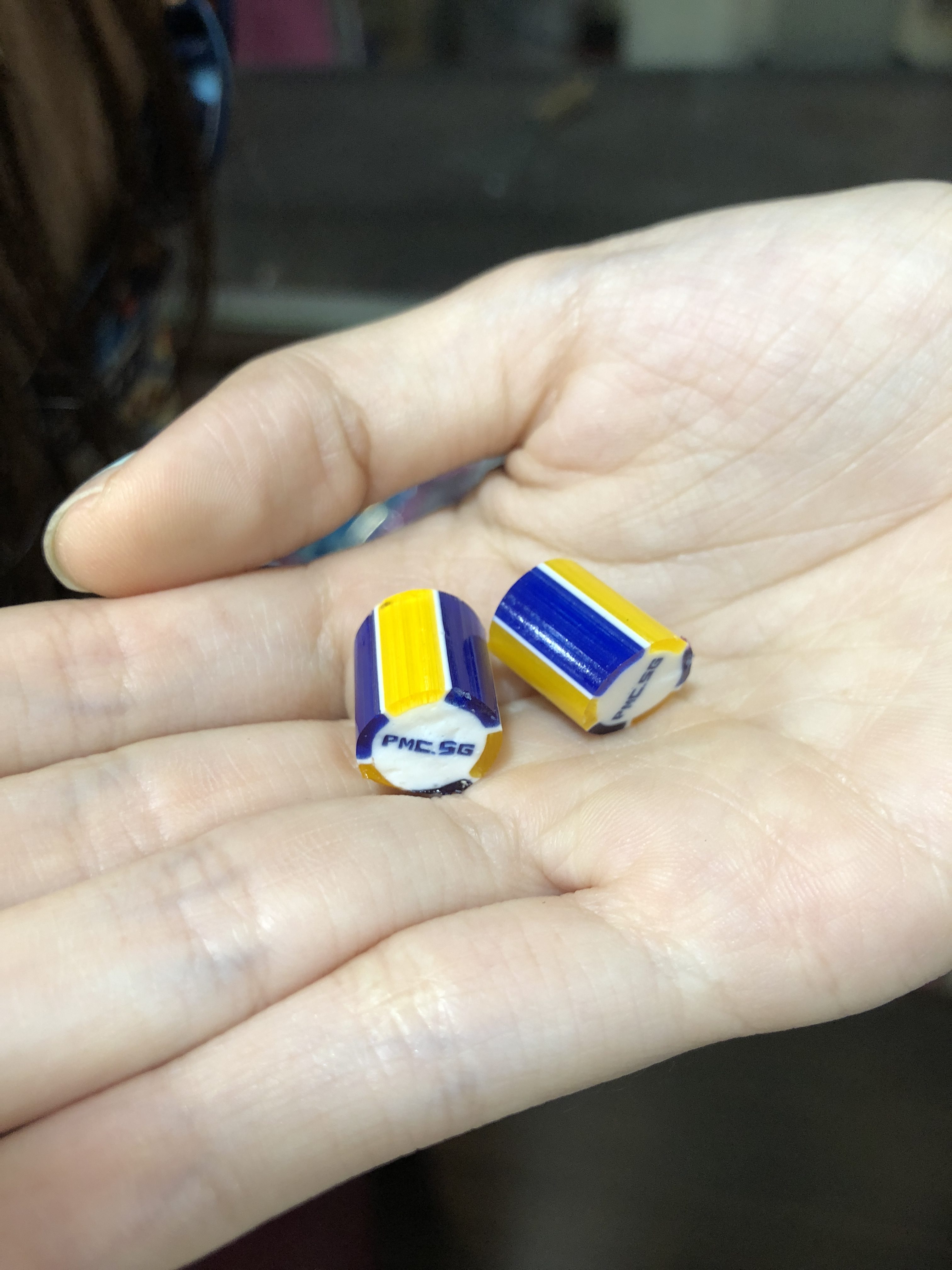

Sticky had an order for a custom design — required a website’s URL. So it was pretty interesting to see how they produced the characters one at a time.

They first had to melt the sugar into a working paste for about 20 minutes. Once melted, they can start the process of making the candy. They have 3 different colors – blue, white, and orange paste for the custom order.

They place the slabs on the cooling rack first and then kneaded it. After a few rounds of kneading, the slabs were stretched on a hook to make it more elastic to work with.

After kneading, they put it on the warm table to work on it.

Once done, they will snip parts of the bigger slab and work on the details from inside-out — starting with the URL. They mold the pieces and then shaped it properly to get the desired effect. The shape is then reinforced with a metal rod.

The process repeats until the entire character is done, wrap it with the white paste and then finally prepare the outer layer.

The outer layer is wrapped around and then they start pulling the giant candy into the smaller signature tubes which is cooled down further with a fan.

Once cooled, the small individual tubes are then cut into the recognizable Sticky candy we know.

Tools:

- Gloves

- Scraper

- Metal Rod

- Hook for stretching the candy

- Scissors

- Fan for cooling down candy

Worksite:

The worksite is open to the public to observe the candy-making proces but only staff could enter the actual site. They have a rack of food coloring and a ‘kitchen’ at the back to prepare the sugar paste for working. In the front, they have large desks – one for keeping the candy paste warm and another that is cool to harden the candy. All their tools are just placed on the desks.

Personal Insights/Pain Points:

I never knew that the candy-making process would be so long and exhausting! You could see the practitioners breaking out a sweat especially with the kneading and forming of the characters. It is pretty labor intensive for pieces with a lot more detail. You need to have an eye to see the characters forming — I didn’t notice it until only halfway through! There was no mold and every detail was formed by the 2 artisans.