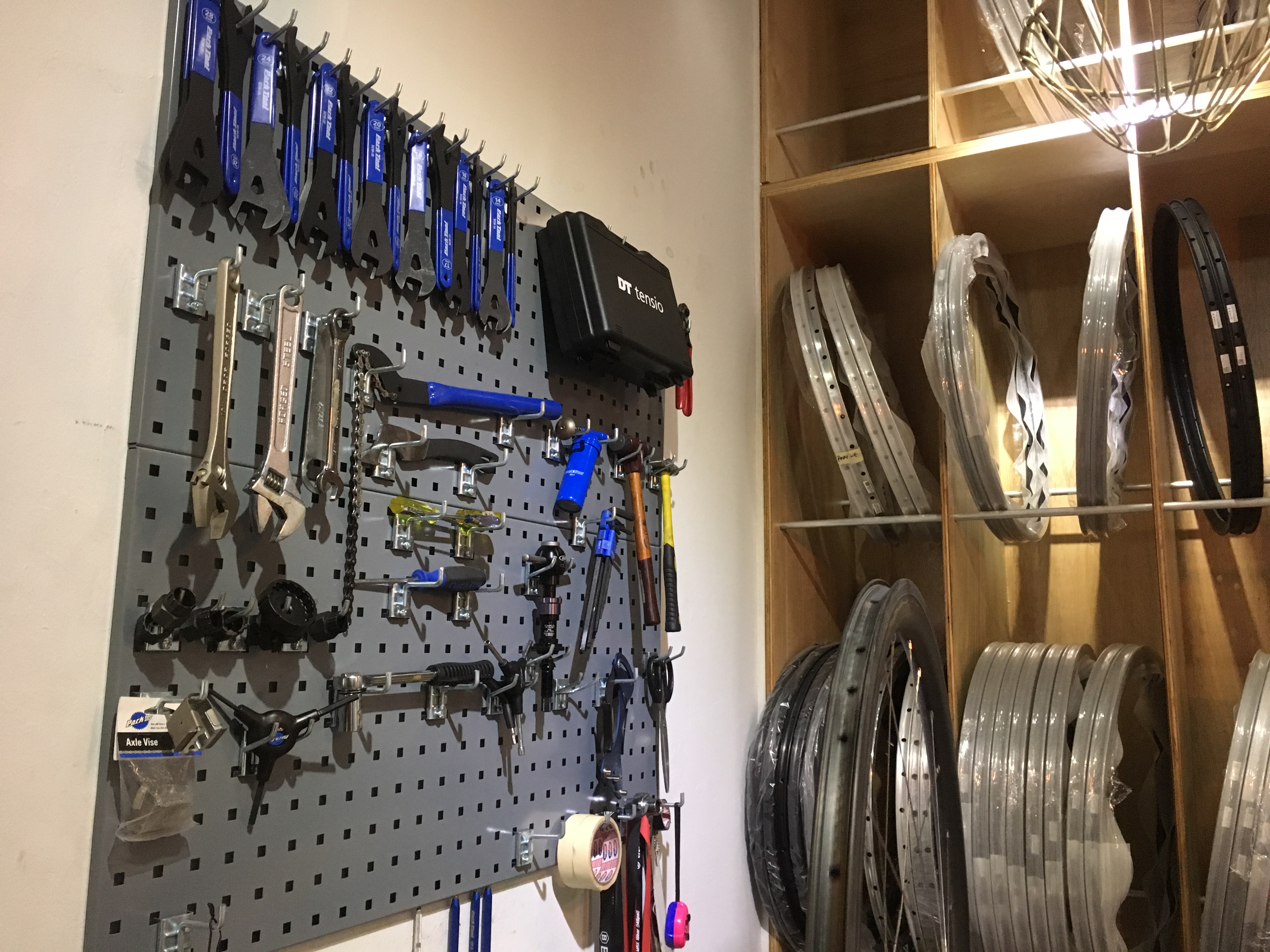

Workshop:

shelf of rims

shelf of spokes

Tools:

- Set Square

- Vernier Callipers

- Spoke Cutter

- Nipples

- Oil

- Screw Driver

- Truing Stand

- Spoke Wrench

- Spoke Tension Meter

- Dishing Tool

Process:

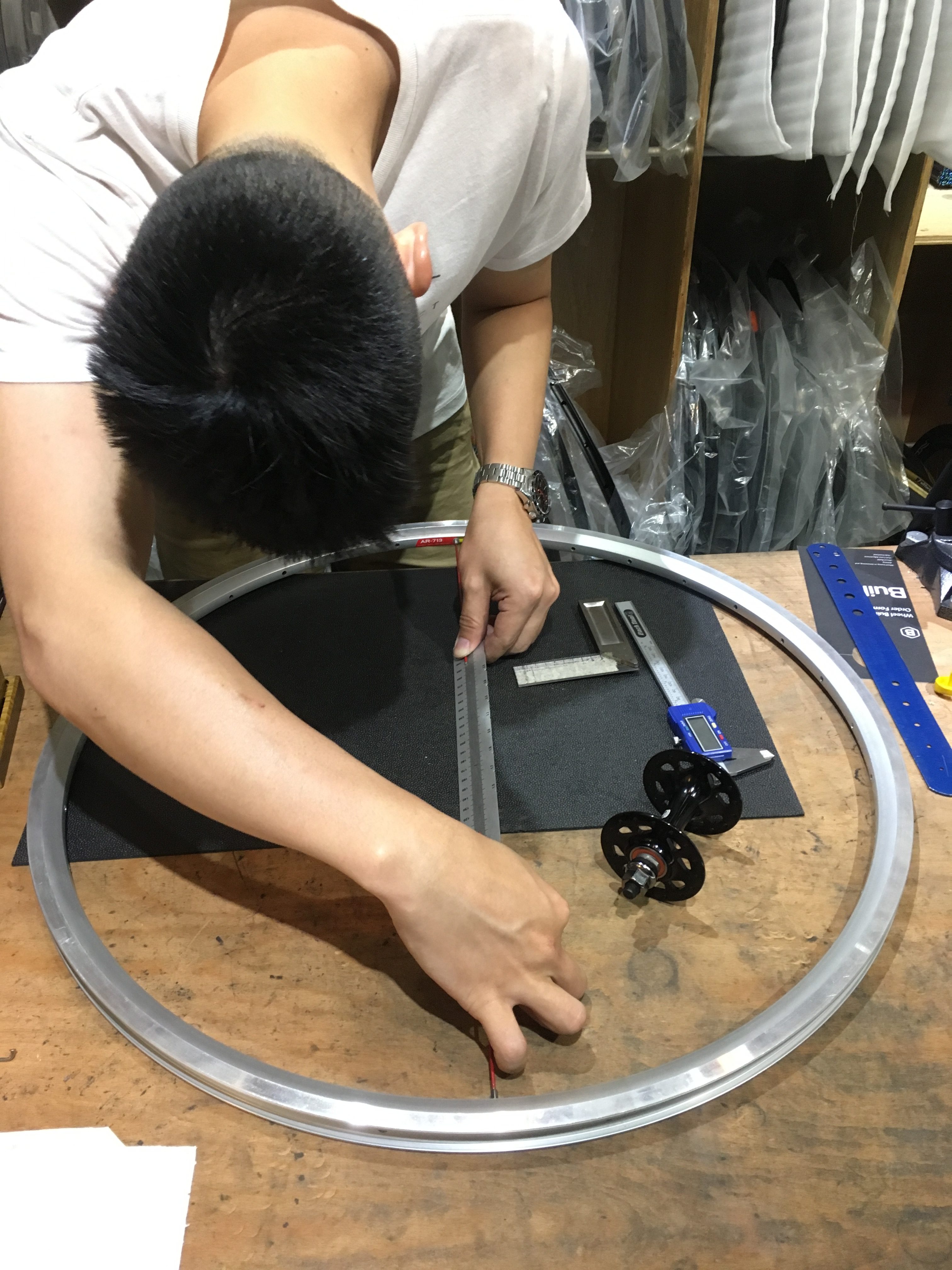

Step 1. Find desired hub and rim, and count the number of spokes required

Step 2. Measure the rim and hub for the spoke length needed

Step 3. Cut the spokes to the correct length using the spoke cutter

Step 4. Count the number of nipples required and oil them

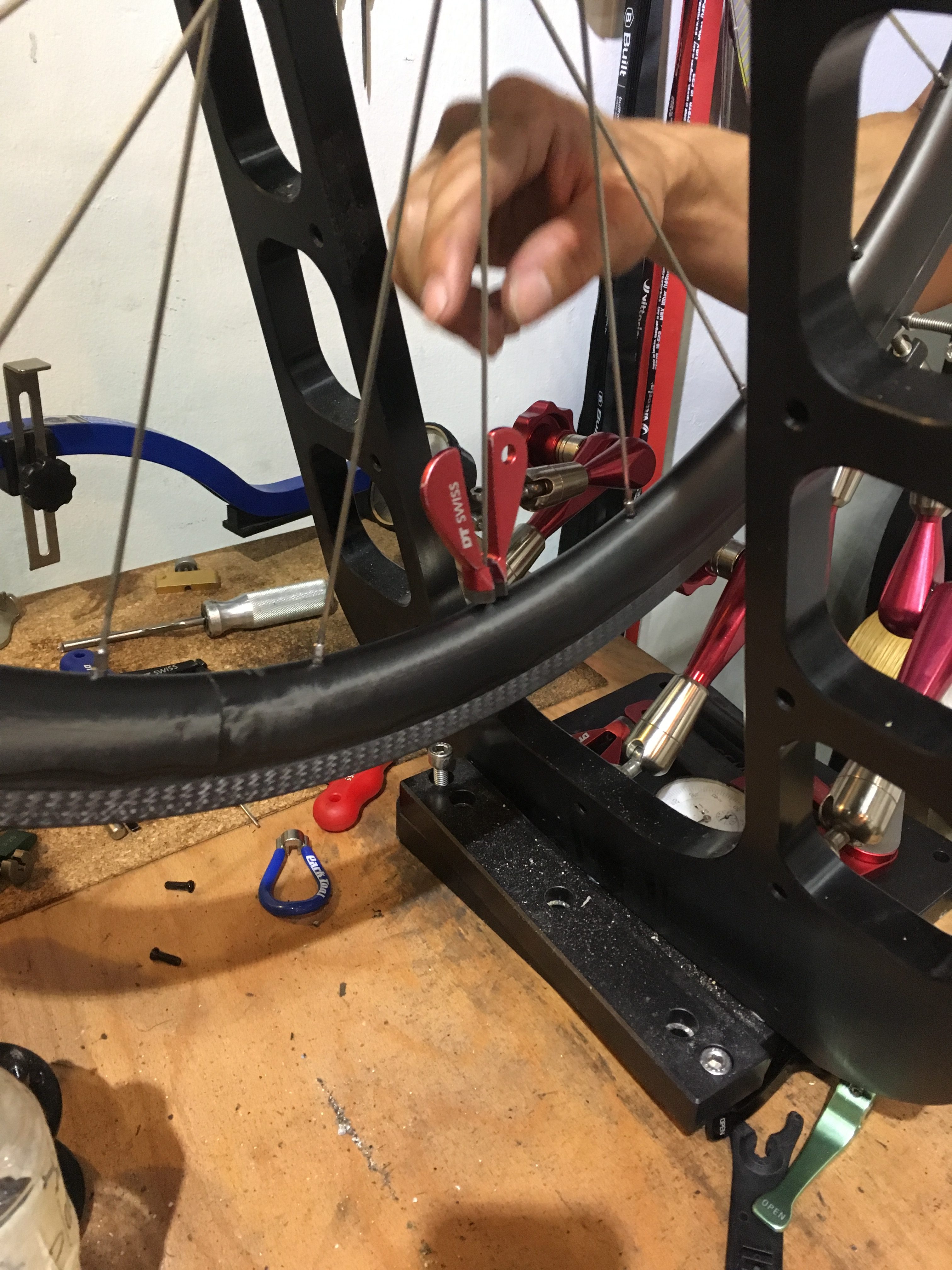

Step 5. Lace the spokes through the rim and the hub using the screwdriver

Step 6. Put the wheel on the truing stand and further tighten the spokes using the spoke wrench

Step 7. Check the tension of the spokes using the spoke tension meter, and ensure that the spokes have the correct and same tension. Adjust along the way.

Step 8. Use the dishing tool to ensure that the hub is in the center of the rim

Pain Points:

Precision is extremely important in building a wheel, especially when safety is of concern.

The back and forth process of checking then adjusting is also extremely tedious.