One of my friends is an engineering undergraduate in NUS and has been involved in tons of projects, where he acted as a product design engineer role. He has ongoing projects with companies ongoing, I paid him a visit in school, he brought me around the FabLab in NUS and walked me through the basics of his work.

Tools Used

- Wire stripper

- Wire cutter

- Crimper

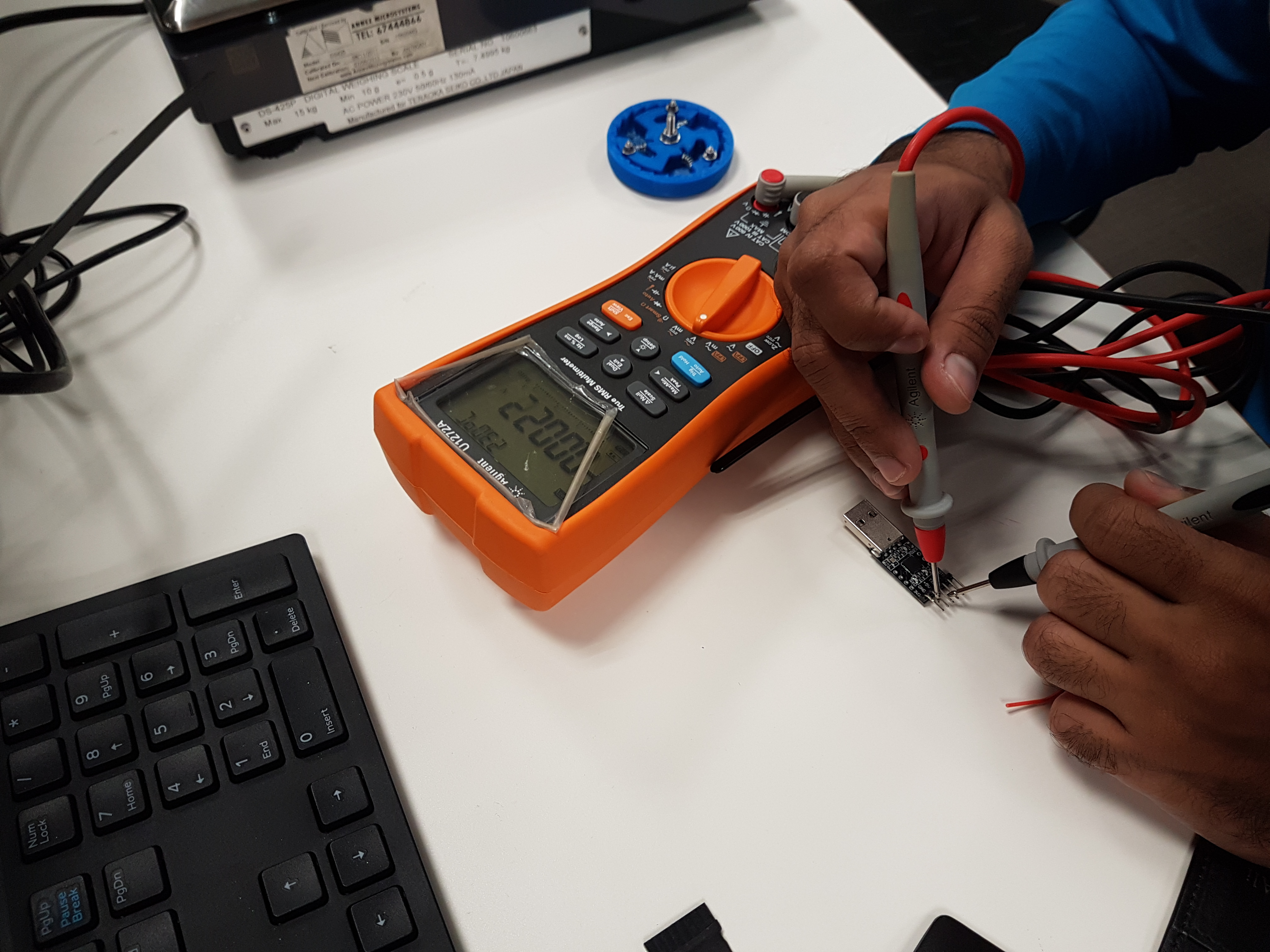

- Multimeter

- Multi-screwdriver

- Digital calipers

- Wires

- Soldering iron

Process

Because he wasn’t working on his project at that point of time and that we agreed to only go through the very basics of his tools are used, he drew up very simple scenarios of when the tools are needed and how it can come in handy. He started off with something very familiar, yet different. The multi-screwdriver: a screwdriver with interchangeable tips. The tip and the driver itself is connected via magnets. I can totally see how this tool can come in handy, and why he said it’s his favourite tool out of all.

Next was the wire stripper, wire cutter, and the crimper. The first two are fairly familiar and simple in its functionality – I mean what it does is literally in its name. But the crimper boggled me at the start. It looked unfamiliar and has a unconventional name. He then showed me how it’s used. The crimper is used to “pinch” and “tighten” specific parts of the wire connectors, such that it will form a snug fit of the wires.

Digital calipers, basically measures the width of any object that you want to measure down to the nearest 0.1 decimal point.

And lastly, the Multimeter, which can measure the voltage, current or resistance of any two points of a circuit. He told me that this is very useful when he wants to check whether there is any drop in current anywhere along the circuit, because that could lead to inefficiency in the device or even the device not working properly.

Workspace

His workspace is basically a small table with tools lying around. He tries his best to keep the workspace as tidy as possible, especially when he works with the larger, electronic tools. And when he’s done using the tools, he will return it to where it belongs, in order to keep his workspace as tidy as possible.

Pain points

I was told that one of the constant issues that he face is that he tends to misplace the different tips of the multi-screwdriver whenever he uses it. The fact that he uses it most often, and that the tips are really small in comparison to other tools, really doesn’t help his cause. It’d be good if the tips that aren’t in use can be easily kept safe, at somewhere that’s easily accessible.